RESISTIVE – (PROJECTED) CAPACITIVE – IR – SAW – COVERLENS

TOUCH

Since the first smart phones, touch has become more and more a necessity rather than an option. Depending on the final product and the environment we are able to supply a range of touch panels and kits.

For smart-home and advertising use, there are special touchscreens that work as a mirror when the display is set to a black screen (or backlight turned off) and upon use, the backlight behind it becomes clearly visible!

In the more recent years the technologies that are most common are the projected capacitive touch and the resistive touch, but every touchscreen technology has advantages and disadvantages.

The factories we work with are most suited to supply:

- PCAP (Projected Capacitive) touch panel

- Resistive 4-wire; 5-wire and 8-wire

- Those 2 technologies easily take up 80% of the market share.

- For some applications other technologies may be better:

- IR touch (InfraRed)

- SAW (Surface Acoustic Wave)

And a special note for:

- EMP touch (Electro Magnetic Pen), optimal “no wear out” pen writing technology

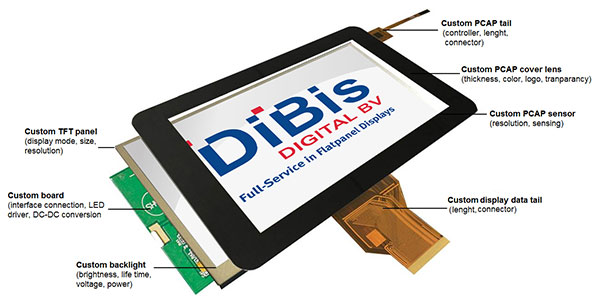

To control the touchscreens we recommend to use a solution from the factory, but the choice is yours concerning a separate touch controller board or a COF (Controller On Flex). The advantage of COF is that it is more low cost. COF tails may even have miniature connectors to insert an I2C or USB cable.

In order to protect the display and the touchscreen, you may want to have a custom cover lens or cover glass. This is even possible for resistive touch, but much more frequently used in combination with PCAP touch. The cover lens or glass can be cut to the desired size and customized in color, shape, logo etc.! Further it is possible to have a cut out (e.g. hole for home button), LEDs for status info and even mini camera’s, speakers and so on.

Due to the fact that almost all applications are different, touchscreen requirements are often different. We welcome customization requests based upon:

- Size

- Performance

- Thickness of coverlens

- Durability

- Transparency

- Controller IC / board

- Bezel color / logo printing

- Adhesive finish for sealing off from the environment, e.g. AR / AG / Anti-smudge / Scratch proof

In case the touch is used in combination with a display we recommend to have the factory take care of the bonding of touch on display. The suppliers have a dust free area and experienced assembly personnel. We determine 3 options:

- DSA (Double Sided Adhesive)

- OCA (Optical Clear Adhesive)

- OCR (Optical Clear Resin)

Please contact our staff to explain the (dis-)advantages.